German energy corridors: a new frontier in Prysmian project management

Head of Project & Contract Management Riccardo Fabbri and his team are re-thinking the way they handle mega projects as they get to work on the German corridors underground energy project.

Dealing with increasing complexity by adding new skills

Every so often, a “unicorn” project comes along that is so unusual that it forces project managers to re-think the way they do their jobs. Projects BU’s Head of Project & Contract Management Riccardo Fabbri and his team are now dealing with such a project as they start work on the three Germany energy corridors, the world’s largest underground cables project.

“We decided to give the German corridors projects a degree of organizational separation from the way we run the rest of our projects - however ensuring a strong governance and control form HQ - because we can’t apply the same rules to these ones,” says Fabbri. “We have completed the set-up phase of the three projects by creating the core team that has picked the first 100 of 250 new hires and has set up three new offices. It’s like starting three new companies. This shows just how big this challenge is.”

Riccardo Fabbri

Head of Project & Contract Management

If the project were simply “just” large, it would already be a huge undertaking: a total of 5,130 kilometers of three underground energy cables systems linking German wind farms in the North Sea to the southern states of Bavaria and Baden-Württemberg, home to BMW and Daimler Benz and other big industries. It is also dramatically strategic, because it crucial to helping Germany meet its energy target of 65% of electricity consumed from renewable sources by 2030.

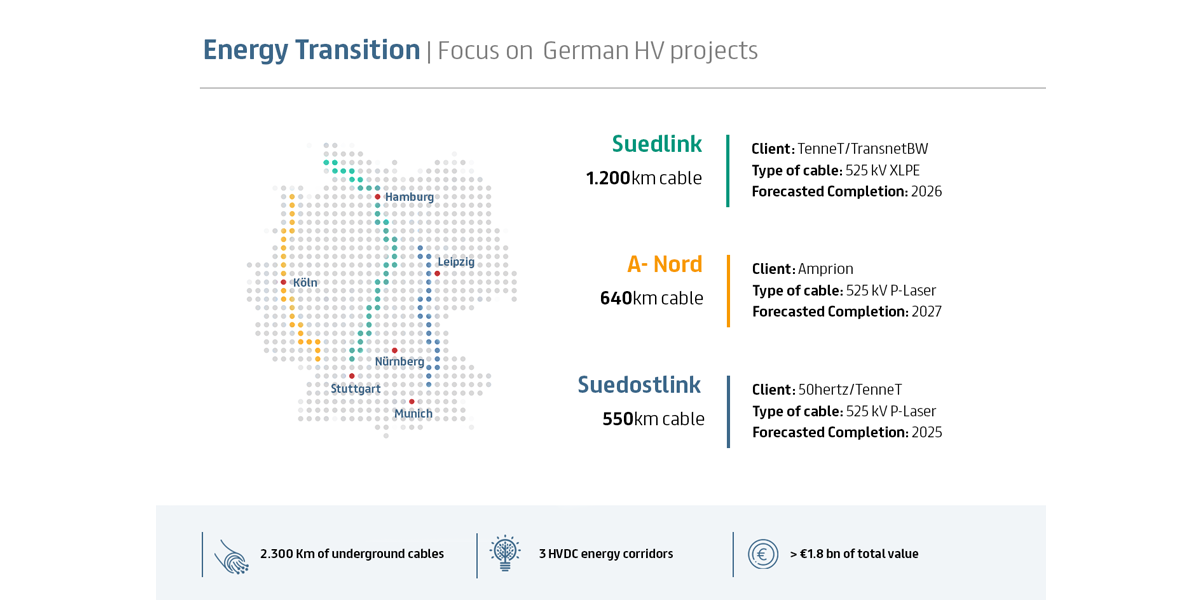

Prysmian will lay about 2,300 kilometers of energy cables, representing around 44% of the total amount of cables necessaries for the three German corridors projects. Of that, 1,200 kilometers will be its newly developed P-Laser 525 kV cable, the first 100% recyclable, eco-sustainable and high-performance cable technology. The total project value for the company exceeds €1.8 billion, epitomizing Group’s principal position in delivering the energy transition by providing cable transmission systems on all three of the German DC corridor projects.

Under Alberto Boffelli, Head of Operations at Projects BU, Prysmian has invested time and energy to improve its project management skills. The results are already paying off. Last year the Projects Business Unit managed 55 cable system projects worth €6 billion in contracts and had its best ever year in terms of operations and smooth project executions due to the lowest variances in terms of costs, and good performances in factories or on vessels. Moreover, the unit’s profit margin grew in 2019 as it adopted more robust product and system development (from design to mass production). As a cherry on the cake, in 2019 it won an IPMA Global Project Excellence Award 2019 for its Ostwind 1 CWA project in the Baltic Sea – the first time it ever competed and the first company competing from the cable market industry.

In 2020, the Projects BU is heading towards the end of the year with >65 projects all around the world for a portfolio value of €8 billion.

Flawless execution is the result of an in-house transformation program carried out by Fabbri over the last two years to bring Prysmian’s project management expertise to a new level amid growing orders, an expanding market, and increasing complexity.

Humanity has always been marked by ambitious building schemes -- project managers have probably been around since Cheops started the Great Pyramids of Giza in 2580 BC. Project management has historically been overseen by engineers with strong technical skills. But running Prysmian’s projects today calls for juggling several demands such as maintaining a dialogue with clients, coping with a host of unknowns, technological innovation, deep knowledge of the sector, and understanding the ins and outs of a contract, says Fabbri. It’s no longer a matter of being “on time, on quality and on budget.”

“The project manager is the person that first and foremost must make sure that we reach a satisfactory outcome for all the stakeholders, mainly clients” he says. “The goal is to reach sustainable satisfaction for everyone.”

That’s why after a recruitment campaign, two years ago Fabbri asked his team of 50 project managers – many of them from outside the cables industry -- to brainstorm ways to transform the way they do their job. They came up with an action plan that led to the creation of a number of new initiatives to further structure, monitor and enhance both Projects and Portfolio performance, also through new KPIs; new execution models; and the mapping of five levels of project complexity. The team also created a new in-house university-style 3-years training program embedded on 3 different seniorities. It starts in November.

“We rewrote our handbook, guidelines and the way we do project management, and we have created our own methods. I believe we are now in the forefront,” he says. “A project manager at Prysmian will now receive a level of training that they won’t find elsewhere, even at a larger company, because our three-year program is completely tailor-made for three different seniority clusters.”

This experience is now the basis for the Projects BU’s biggest challenge yet.